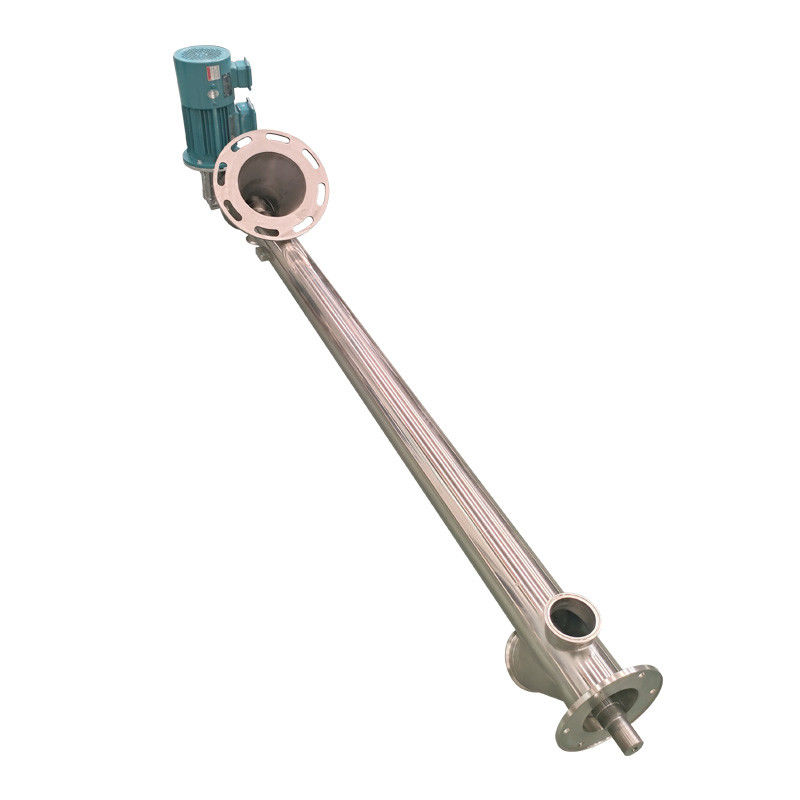

Schraubförderer

Produktbeschreibung

Schraubförderer sind in der industriellen Produktion verbreitete Materialfördergeräte, die Materialien durch die Drehung von Schraubblättern in einen geschlossenen Kanal schieben.Die Struktur dieser Maschine ist nicht kompliziert.Der Kern besteht aus einer rotierenden Welle mit Klingen, U-förmigen oder röhrenförmigen Materialtruhen und ist mit Komponenten wie Antriebsmotoren ausgestattet.,in der Lage sein, Materialien in horizontaler oder geneigter Richtung zu füttern, und gut versiegelt sein, um Materiallecks oder Staubkontamination zu verhindern.Von der Lieferung von Düngemitteln und Pigmenten in Chemieanlagen bis zum Transport von Weizen und Mehl in Getreidemühlen, und dann zum Transport von Zement und Sand in Baustofffabriken, kann es an vielen Orten verwendet werden, um Materialien wie Pulver und Granulate kontinuierlich zu transportieren.Es ist flexibel und bequem zu bedienen.

Arbeitsprinzip

Das Funktionsprinzip eines Schraubförderers basiert auf der mechanischen Übertragung: Wenn die Antriebseinrichtung die Schraubwelle dreht,die Schraubblätter drehen sich entsprechend und üben einen axialen Antrieb auf das Material ausAufgrund der Reibungskraft zwischen dem Material und der Innenwand des Trogs und der Schwerkraftwirkung auf das Material selbst kann es nicht zusammen mit den Klingen rotieren.unter dem Schub, bewegt es sich entlang der Achsrichtung des Trogs vom Fütterungs- bis zum Entladungsport und ermöglicht so einen kontinuierlichen Materialtransport.Die Beförderungsrichtung kann flexibel geändert werden, indem die Drehrichtung der Schraubblätter angepasst wirdDieser Mechanismus, der die Drehkraft in axalen Schub durch die Helicalstruktur umwandelt, ermöglicht es dem Gerät, die Förderanforderungen von Pulvermaschinen effizient zu bewältigen.Granulat- und Kleinstblockmaterialien.

Merkmale des Erzeugnisses

1Kompaktes und flexibles Bauwerk: Die Ausrüstung ist exquisit angeordnet, nimmt eine kleine Fläche ein und kann sich auf horizontale, geneigte oder sogar vertikale Installationsumgebungen anpassen.so dass sie leicht in verschiedene Verbindungen der Produktionslinie integriert werden.

2Stabile Förderleistung: Die Spiralblätter drehen sich kontinuierlich, um Materialien zu drücken, wodurch ein gleichmäßiges und kontinuierliches Förderverfahren erzielt wird, das besonders für Pulver-, Granulat- und kleine Blockmaterialien geeignet ist.

3. Ausgezeichnete Dichtungsleistung: Der geschlossene Materialtrog kann effektiv verhindern, dass Staub ausläuft und Materialien feucht werden,Verringerung der Umweltverschmutzung bei gleichzeitiger Gewährleistung der Reinheit des Materials, die Anforderungen an saubere Szenarien in der Lebensmittel-, Chemie- und anderen Industrie erfüllen.

4- Bequeme Richtungsregelung: Durch Änderung der Drehrichtung der Spiralblätterder Materialtransportweg kann leicht gewechselt werden, um die Anforderungen an die Materialübertragung verschiedener Prozesse zu erfüllen.

5. Niedrige Wartungskosten: Die Kernkomponenten haben eine einfache Struktur und der Austausch von anfälligen Teilen ist bequem. Nur regelmäßige Inspektion und Schmierung sind täglich erforderlich,Verringerung der Kosten für die Betriebsunterhaltung.

Anwendungsindustrie

Chemische Industrie: Es wird für den Transport von pulverförmigen oder granularen chemischen Rohstoffen wie Sodaasche, Düngemitteln und Pigmenten verwendet und spielt eine Rolle bei der Verpackung, Vermischung,und Verpackung von Materialien- Ich weiß.

Getreide und Lebensmittelverarbeitung: Es eignet sich für den Transport von Stoffen wie Weizen, Mais, Mehl und Zuckerpulver und kommt häufig in der Getreidelagerung, Futtermittelverarbeitung,und Lebensmittelproduktionslinien- Ich weiß.

Auf dem Gebiet der Baustoffe: Es kann Baustoffe wie Zement, Kohlepulver und Sandpartikel transportieren und wird in Betonmischanlagen weit verbreitet,Baustoffspeicher- und Transportsysteme- Ich weiß.

Metallurgie und Bergbau: Es wird für den Transport von Materialien wie Erzpulver, Kohlepulver und Koks verwendet.und realisiert Materialübertragung in Prozessen wie Erzscreening und Schmelzvorbehandlung- Ich weiß.

Umweltschutz und Landwirtschaft: Es kann umweltfreundliche Materialien wie Schlamm und Strohpellets behandeln oder Saatgut, Futtermittel usw. in der Landwirtschaft transportieren,Erfüllung der Materialtransportbedürfnisse verschiedener Szenarien.

Produktparameter

| Modell |

Durchmesser des Förderrohrs |

Macht |

Volumen der Hopper |

Winkel (Grad) |

| Der Begriff "Fördermittel" |

133 mm |

0.75-4KW |

200L oder nach Maß |

30 bis 60 |

| Der Begriff "Fördermittel" |

159 mm |

0.75-4KW |

| Der Begriff "Fördermittel" |

219 mm |

1.5-4KW |

| Der Begriff "Fördermittel" |

273 mm |

2.2-4KW |

| Bitte konsultieren Sie uns für weitere Modelle |

|

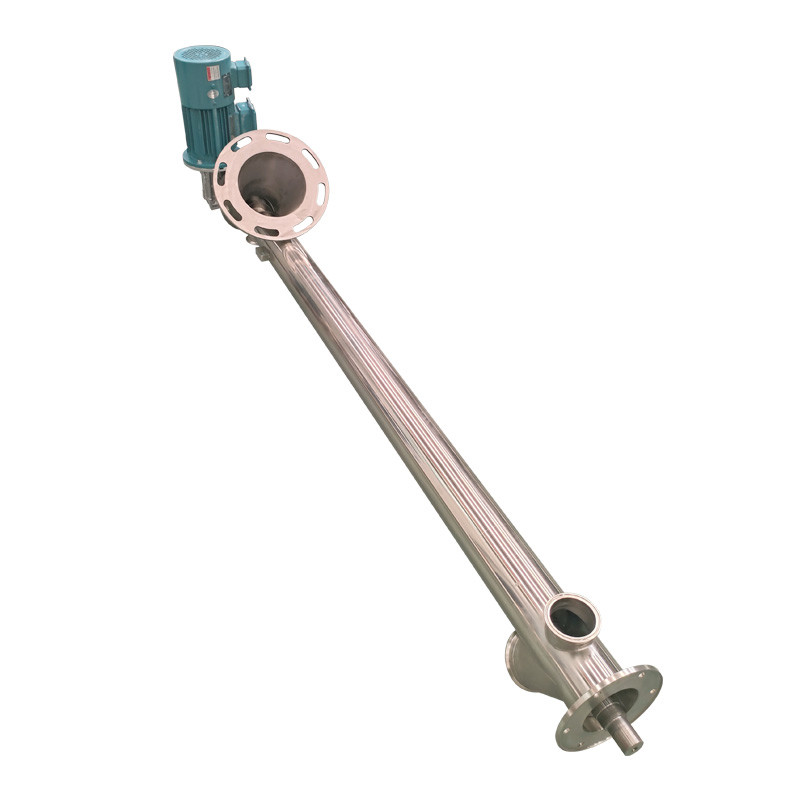

Produktanzeige

Einzelheiten zum Produkt

Anwendung des Produkts

Verpackung und Versand

Warum Sie uns wählen

Über uns

Wir sind seit 13 Jahren auf die Produktion von Screening- und Transportgeräten spezialisiert.Und wir haben für viele große UnternehmenDazu gehört auch der weltweit führende Hersteller von Schwingbildschirmen, Sweco, USA.

Wir sind in der Lage, unsere Produkte für seine chinesische Region zu verkaufen.Schweden und anderen Ländern.

Wir begrüßen Kunden oder Händler, unsere Fabrik zu besuchen und alles für Sie zu arrangieren.Fabrikadresse: Westlich des Industrie- und Handelsbüros von Da Zhaoying Town, Stadt Xinxiang,Provinz Henan.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!