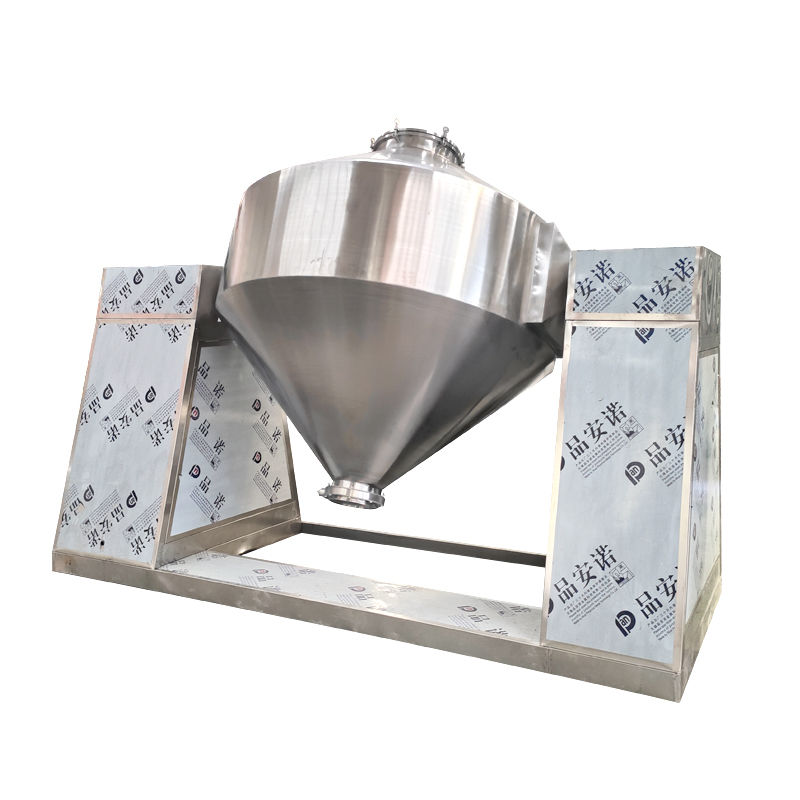

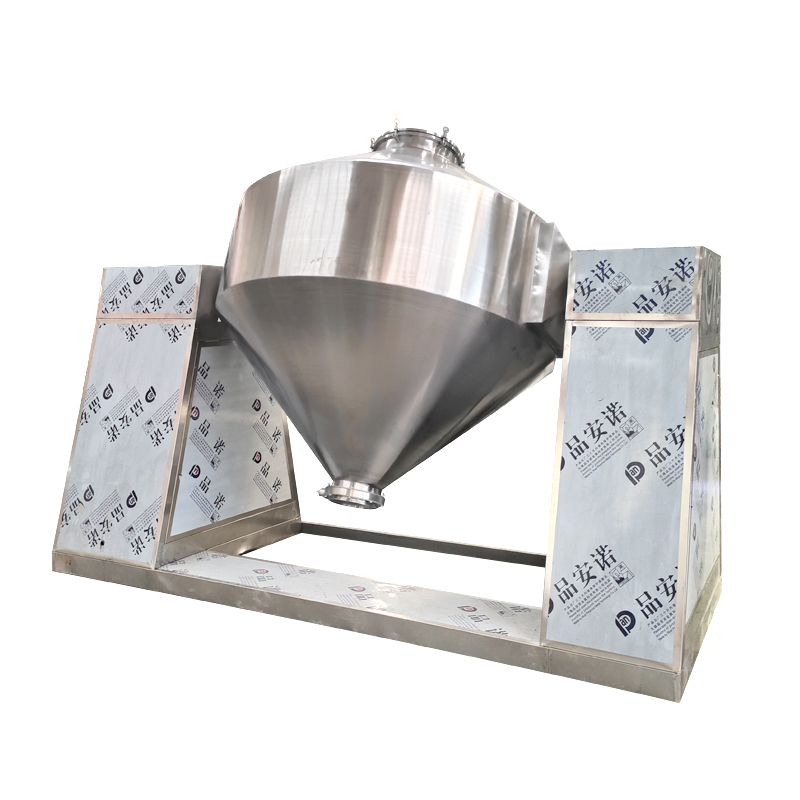

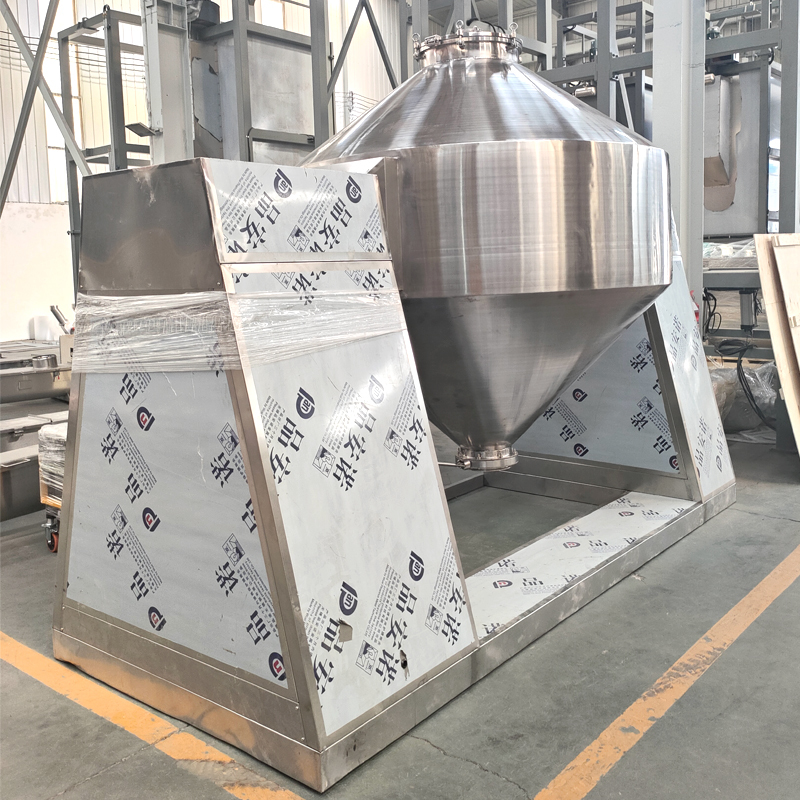

Doppelkegelmischer

Produktbeschreibung

Der Doppelkegelmischer ist eine in Industriezweigen wie Pharma, Lebensmittel und Chemie weit verbreitete Pulvermischgeräte.mit einer Leistung von mehr als 50 W und einer Leistung von mehr als 50 W,Es verfügt über eine hohe Mischeffizienz, keine toten Ecken und minimale Rückstände.Es eignet sich für das Mischen von trockenen und halbtrockenen Materialien und ist in Szenarien, in denen eine hohe Mischgenauigkeit und Materialflüssigkeit erforderlich sind, außergewöhnlich gut geeignet.

Arbeitsprinzip

Nachdem die Ausrüstung in Betrieb genommen wurde, treibt der Motor die Mischkammer, die aus den beiden kegelförmigen Zylindern besteht, mit konstanten Geschwindigkeiten um eine horizontale Achse herum.Die Materialien in den kegelförmigen Kammern werden während der Drehung der Zylinder kontinuierlich auf eine bestimmte Höhe angehobenWährend dieses Prozesses verursacht die kegelförmige Struktur, dass die Materialien beim Absteigen Kreuzdiversionen bilden.Kombiniert mit der Scherkraft und der Diffusionswirkung durch die Rotation der Zylinder, können verschiedene Arten von Pulver- oder Granulatmaterialien vollständig in Berührung kommen und gleichmäßig gemischt werden, ohne gezwungen zu werden, um letztendlich den gewünschten Mischwirkung zu erzielen.

Merkmale des Erzeugnisses

1Hohe Mischgleichheit: Dank der kegelförmigen Struktur und der durch die Drehung erzeugten Scher- und Diffusionswirkung können die Materialien nahtlos gemischt werden.besonders geeignet für pulverförmige oder granulare Materialien mit guter FlüssigkeitDie Mischgenauigkeit kann den Bedürfnissen der meisten industriellen Anwendungen gerecht werden.

2Minimale Materialschäden: Ohne Zwangsräumkomponenten mischen sich die Materialien unter dem Einfluß der Schwerkraft natürlich und verringern die Kompression, Zerkleinern oder Verschleiß von zerbrechlichen Materialien.

3. Niedrige Rückstände: Die Innenwand ist glatt und die Konusstruktur ist vernünftig.die zu einer geringen Restmenge im Inneren der Ausrüstung führt, was für die Reinigung und den Wechsel der Materialtypen praktisch ist.

4. Einfache Bedienung: Die Struktur ist relativ einfach. Der Mischeffekt kann durch Steuerung der Drehgeschwindigkeit und Zeit angepasst werden.Der Automatisierungsgrad kann je nach den Anforderungen verbessert werden..

5. Starke Anpassungsfähigkeit: Durch die Konfiguration von Funktionen wie Vakuumzufuhr, Sprühtomisierung, Jackenheizung / Kühlung usw. kann es auf Trocknung, Reaktion und andere Szenarien erweitert werden,geeignet für verschiedene Industriezweige wie die Medizin, Lebensmittel und Chemie.

Anwendung

1Hohe Mischungenähnlichkeit: Die kegelförmige Struktur ermöglicht den freien Fluss der Materialien und reduziert die Stagnation.Hohe Gleichförmigkeit des Gemischs: Die kegelförmige Struktur ermöglicht den freien Fluss der Materialien, wodurch die Stagnation verringert wird, besonders geeignet für Pulver/Partikel mit ähnlicher Dichte.Die kegelförmige Struktur ermöglicht es den Materialien, frei zu fließen, die Stagnation reduziert, besonders geeignet für Pulver/Partikel mit ähnlicher Dichte.

2. Niedriger Rückstandsanteil: Glatte Innenwand + keine tote Ecke, der Rückstand nach dem Entladen ist viel geringer als bei Geräten mit Rührrädern, geeignet für hochwertige Materialien.

3. Gute Dichtungsleistung: Die vollständig geschlossene Struktur reduziert Staublecks und erfüllt die sauberen Produktionsstandards von Industriezweigen wie Medizin und Lebensmittel.

4Einfache Wartung: Keine komplexen Komponenten, geringe Ausfallrate und geringere Wartungskosten als bei Paddel- oder Blade-Geräten.

5. Niedrigerer Energieverbrauch: durch Schwerkraft und Rotation gemischt, keine Notwendigkeit für einen Hochleistungsmotor und die Betriebskosten sind sparsamer.

6. Weite Anwendbarkeit: Geeignet zum Trocknen von Pulvern/Partikeln und geringen Mengen flüssiger Mischungen mit geringer Beschädigung fragiler Materialien.

Produktparameter

| Modell |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

Produktionskapazität

(kg/Zeit)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

Voller Volumen

(Kubikmeter)

|

0.3 |

0.5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

Mischzeit

(min)

|

4 bis 8 |

4 bis 8 |

6 bis 12 |

6 bis 12 |

6 bis 12 |

6 bis 15 |

6 bis 15 |

6 bis 15 |

|

Motorleistung

(KW)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| Zylinderdrehzahl (RPM) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

Abmessung

(L*W*H)

|

1680*650

*1600

|

2080*750

* 1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

* 2450

|

2980*1580

*2800

|

3500*1800

* 3000

|

3980*2000

*3200

|

| Gewicht (kg) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

Produktionslinie-Diagramm

1Der Arbeiter entlässt den Beutel auf der staubfreien Müllbelagsstation, da in der Maschine ein Staubsammler vorhanden ist, so daß der Staub fliegt.

2Die Siebmaschine entfernt den Klumpen oder das große Material und lässt nur kleinere Materialien in das Fördersystem fließen.

3Der Vakuumförderer transportiert das Material zu einem Puffer- oder Lagertropfen und wartet auf die Mischung.

4. Wenn Sie mischen müssen, beginnt die Vakuum-Feeder Arbeit, transportieren Sie das Material aus dem Hopper zum doppelten Kegel Mischer

5Nach dem Mischen wird das gemischte Material in eine Verpackungsmaschine transportiert, nach dem festgelegten Gewicht verpackt und dann die Tüte versiegelt.

In diesem System ist der gesamte Transportprozess versiegelt, um Hygiene und Sicherheit zu gewährleisten.

Anzeige der Details

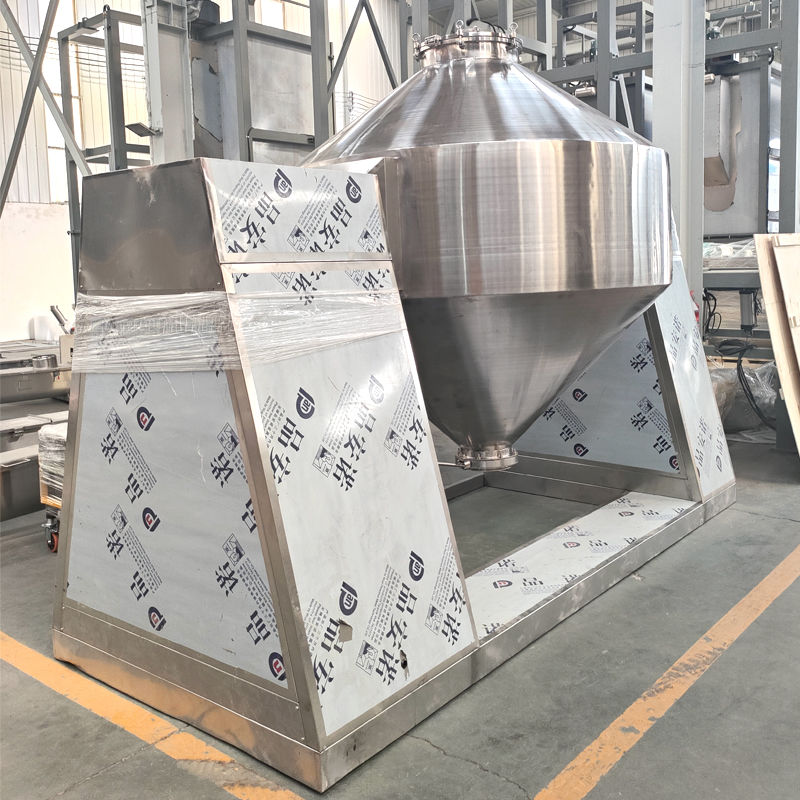

Produktanzeige

Verpackung und Versand

Warum haben Sie uns gewählt?

Über uns

Unternehmensprofil

Wir haben uns seit 13 Jahren auf die Produktion von Screening- und Übertragungsgeräten spezialisiert. Chinas Vibrationsbildschirmindustrie Top drei. Und wir haben für viele große Unternehmen Matching und OEM gemacht.Einschließlich des weltweit führenden Herstellers von Schwingbildschirmen, Sweco, USA, wir haben OEM für seine China Region. und unsere Produkte werden oft nach Australien, Thailand, Indonesien, Neuseeland und anderen Ländern exportiert.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!